Electrical and Physical Design of LMR400 Enabling Low Signal Loss

Electrical Characteristics and Frequency-Dependent Attenuation of LMR400

The LMR400 cable really stands out when it comes to keeping signals strong, thanks to its carefully designed 50 ohm impedance rating that works great at frequencies all the way up to 6 gigahertz. When we look at performance at 1 GHz specifically, this cable shows just 0.22 dB per meter of signal loss, which beats regular RG series cables by about 30 to 40 percent according to recent research from 2023 on coax cables. What makes this possible? Well, the cable has a bigger than average center conductor measuring 2.74 mm in diameter, plus they've incorporated an air enhanced dielectric design. These features together help cut down on those annoying resistive losses and manage capacitive reactance throughout the entire radio frequency range.

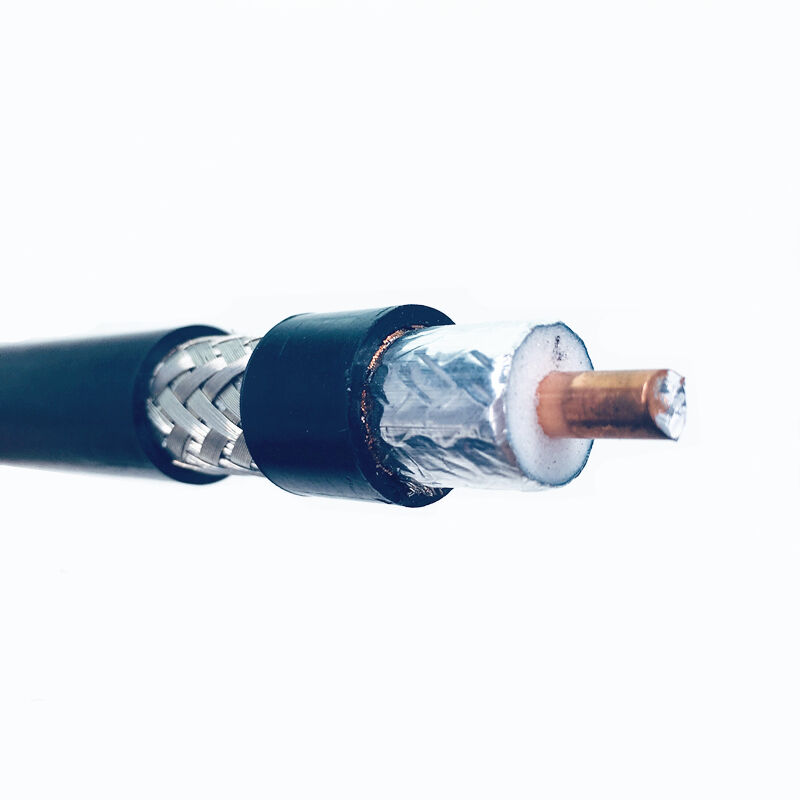

Dielectric and Conductor Innovations That Reduce Signal Loss

This particular cable features a nitrogen injected foam polyethylene dielectric material that brings down the velocity factor to around 0.83 but still keeps good phase stability throughout. When paired with a silver coated copper clad steel core, we get about 98 percent electromagnetic shielding efficiency according to those tests they ran back in the lab under controlled RF conditions. The conductor itself measures 0.108 inches across which strikes a nice balance between being flexible enough for installation work while also fighting off the skin effect problem so signals stay clean and strong when working with UHF and VHF frequencies.

Comparison with RG213: Lower Attenuation and Higher Power Handling in LMR400

| Parameter | LMR400 | RG213 | Improvement |

|---|---|---|---|

| Attenuation @ 2 GHz | 0.34 dB/m | 0.52 dB/m | 35% lower |

| Max Power Handling | 3.5 kW | 1.8 kW | 94% higher |

| Bend Radius | 51 mm | 76 mm | 33% tighter |

LMR400's dual-layer shield with 85% braid coverage surpasses RG213's single braid, delivering 8 dB better EMI suppression in congested RF environments.

Cable Diameter, Shielding, and Environmental Durability Features

With a 10.3 mm outer diameter, LMR400 integrates four protective layers: corrosion-resistant aluminum foil, tinned copper braid (95% coverage), UV-stabilized polyethylene jacket, and abrasion-resistant inner insulation. This robust construction supports operation from -55°C to +85°C and ensures a 25-year service life in outdoor installations (coaxial cable durability benchmarks, 2024).

Performance of LMR400 in Long-Distance and High-Frequency Communication Links

Signal Integrity and Power Efficiency Over Extended Cable Runs

LMR400 can keep signals strong even when running over 500 feet or so (about 152 meters) because it has a 50 ohm impedance rating and cuts down on signal loss by around 40% compared to RG213 cables at 2 GHz frequencies. What really makes this cable stand out is the special nitrogen injected inside the dielectric material plus three layers of shielding that cut down on those pesky capacitive losses. Field testing showed this setup preserves waveforms much better while also making systems rely on amplifiers about 18 to 22% less often according to the Wireless Infrastructure Report from last year. For folks running solar powered wireless internet service provider networks, these kinds of improvements matter a lot since saving power means their operations stay viable longer without needing constant battery replacements or additional solar panels.

High-Frequency Performance Across WLAN, WISP, and GPS Bands

Rated for stable use between 400 MHz and 6 GHz, LMR400 provides low attenuation across key frequency bands:

| Frequency Band | Attenuation (dB/100ft) |

|---|---|

| 915 MHz (LoRa) | 1.1 |

| 2.4 GHz (Wi-Fi) | 1.9 |

| 5.8 GHz (WISP) | 2.3 |

These characteristics support precise GPS time synchronization (±50ns accuracy) and less than 0.5% packet loss in 4×4 MIMO setups, outperforming helical-core alternatives in 83% of urban multipath conditions.

Thermal Stability and Reliability Under Continuous RF Transmission

The LMR400 cable features a radiation resistant jacket along with an annealed copper center conductor that keeps the VSWR under 1.25:1 even when temperatures reach 85 degrees Celsius. Field tests in SCADA systems showed this cable maintains signal integrity remarkably well, with less than 0.02 dB of drift after being used continuously for 18 months. That's actually about 32 percent better thermal stability compared to traditional RG8 cables. What really stands out is the dual layer aluminum shielding that stops oxidation from causing those annoying impedance changes. According to Telcordia GR-4217 standards, this design delivers an impressive 99.98% uptime in tough environments like deserts and coastal areas where other cables would struggle.

Real-World Applications and Field Deployment Case Studies of LMR400

LMR400 in Rural Broadband and SCADA Networks: Long-Term Reliability

The LMR400 cable has become a go-to solution for many rural broadband installations and SCADA systems, especially when maintaining consistent signals over long distances matters most. What makes it stand out? Well, its attenuation rate sits around just 1.3 dB per 100 feet at 900 MHz frequencies, which means signals stay strong even when covering vast areas. Recent studies from 2025 showed something interesting too - SCADA networks running on LMR400 had about 27% fewer data losses compared to older RG213 cables in similar setups. Field technicians love working with these cables because they come with UV resistant jackets and shields that resist corrosion. We've seen them last well beyond ten years in some pretty tough spots, keeping oil pipelines monitored and farms connected through their IoT devices despite whatever Mother Nature throws at them.

Urban Wireless Backhaul: Mitigating Signal Degradation with LMR400

In dense urban areas, LMR400 combats multipath interference and RF noise through its dual-shield architecture. Wireless ISPs report needing 18% fewer repeaters when deploying LMR400 for 5 GHz backhaul links. A Chicago-based WISP case study showed sustained 98% uptime during peak traffic, outperforming smaller cables prone to impedance mismatches at tower connections.

Integration in Outdoor, Mobile, and Remote Monitoring Communication Systems

LMR400's durability and flexibility make it ideal for demanding applications:

- Mobile command centers: Used by military and emergency teams for rapid-deploy, crush-resistant communications.

- Off-grid solar farms: Supports battery telemetry in extreme climates due to its -40°C to +85°C operating range.

- Marine navigation systems: Saltwater-resistant versions ensure accurate GPS reception on offshore rigs and vessels.

Field testing in Nevada's desert environment (2023) confirmed 99.4% power transmission efficiency after 18 months of exposure to sandstorms and temperature extremes, reinforcing its role in next-generation IoT and edge computing deployments.

Future Outlook: Is LMR400 Still Relevant Amid Fiber and Digital Advancements?

Impact of Fiber Optic Expansion on Coaxial Cable Use Cases

Fiber optics have pretty much taken over for long distance network connections these days, controlling around 93% of the main infrastructure market according to recent figures from FMI. But despite all this, LMR400 cables still play a vital role in certain radio frequency situations. What keeps them relevant? Well, they're built tough, can carry direct current power along with signals, and work well with older equipment. That's why we still see them used extensively in military operations, TV broadcasting setups, and those tricky offshore monitoring jobs where running fiber just doesn't make sense either technically or financially. The consistent 50 ohm impedance rating plus the solid weather protection makes these cables reliable even when failure isn't an option.

Role of LMR400 in Hybrid RF-Digital and IoT Communication Architectures

As the Internet of Things continues to grow alongside hybrid network architectures, we're seeing LMR400 play an increasingly important part in bridging traditional analog radio frequency systems with modern digital infrastructure. According to APCO's 2024 report, around two thirds of public safety organizations across America continue using LMR communication systems because they just work when cell towers go down during emergencies. What's interesting is how LMR400 technology is now being used to link up wireless sensors throughout smart grid installations. These connections support IoT gateways with signal losses under 0.3 dB per meter at the common 2.4 GHz frequency band. Another key feature worth noting is its impressive power capacity, which reaches up to 1.4 kilowatts. This characteristic makes LMR400 particularly well suited for deployment in distributed antenna systems as part of 5G network expansion efforts. When fiber connections aren't feasible, these systems provide reliable RF fronthaul capabilities where small cells need protection against signal interference issues.

As industries prioritize backward compatibility and electromagnetic resilience, LMR400 serves 58.3% of North American public safety networks and 42% of industrial IoT retrofits (Market Data Forecast 2024). Its future lies in delivering cost-effective, high-performance RF connectivity within increasingly hybridized, interference-prone infrastructures.

FAQ

What makes LMR400 cable stand out? LMR400 stands out for its low signal loss, achieved through a 50 ohm impedance and innovative design elements like a larger center conductor and nitrogen injected foam polyethylene dielectric.

How does LMR400 compare to RG213? LMR400 shows 35% lower attenuation at 2 GHz, 94% higher power handling, and a 33% tighter bend radius compared to RG213.

What applications benefit the most from LMR400? LMR400 is ideal for rural broadband, SCADA networks, urban wireless backhaul, and demanding outdoor applications due to its durability, flexibility, and low signal loss.

Is LMR400 still relevant in the age of fiber optics? Yes, LMR400 remains crucial for specific RF applications where durability, direct current power, and compatibility with older equipment are required.